Company Director, Mr Phil Evans from Pre Metro Operations Ltd, in collaboration with Beverley Nielsen representing UltraLight Rail Partners Ltd, accessed support under the SME Support Programme funded by the European Regional Development Funding (ERDF) and delivered by the Black Country Innovative Manufacturing Organisation (BCIMO).

The support enabled Pre Metro Operations and the Ultra Light Rail Partners to come together and explore the potential commercial routes which would enable them to progress their vision of delivering a zero-emission lightweight affordable rail-based transport solution which is non-electrified.

The support involved an interactive discovery workshop, followed by an insights session and feedback presentation which included three commercial opportunities for the team to consider. In addition to this, the support provided a profile-raising advert delivered by our collaborative partners Rail Business Daily.

Beverley Nielsen, Chairman, Ultra Light Rail Partners, said: “The discovery workshop with BCIMO and Rail Business Daily was particularly helpful in that both these highly experienced parties really understand our business, as well as the innovation and commercial challenges we’re pursuing, together with the policy and regulatory backdrops.

“The routes ahead and potential partners suggested make sense and were not previously known to us or even thought of as possibilities. As a startup any profile-raising is always helpful. We see this support package as a key stepping stone in bringing our affordable, sustainable rail solutions to market.”

Brought to life by the BCIMO SME Support Programme

“The discovery workshop with BCIMO and Rail Business Daily was particularly helpful in that both these highly experienced parties really understand our business, as well as the innovation and commercial challenges we’re pursuing, together with the policy and regulatory backdrops."

- Beverley Nielsen, Chairman, Ultra Light Rail Partners

ULRP’s mission is to design and deliver the world’s most cost-effective, environmentally friendly public transport

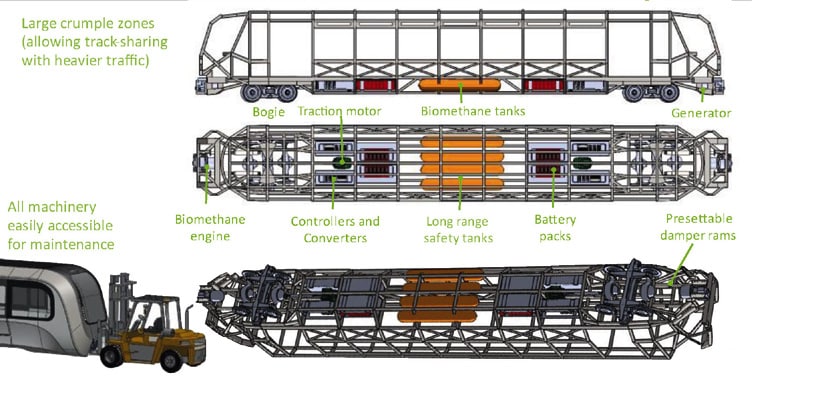

The ULRP concept centres on the BioUltra, a biomethane or green hydrogen powered train and tram family of vehicles allowing rail-based systems to be used much more widely as the BioUltra Zero Emissions Lightweight Transport (B∅LT) system. Ultra light rail vehicles have an axle weight of under / equal to 5 tonnes.

ULRP aims to produce an integrated solution drawing on locally produced energy and materials from local supply chains. Products include – the BioUltra train, BioTram, BioRefueling systems, Green gas retrofit activity and no dig railtrack, a ‘glue in the road’ track.

Products:

The BioUltra and BioTram

ULRP’s public rail-based transport system is based on the BioTrain and BioTram’s integrated infrastructure which can operate on standard rail lines.

This cost-effective family of BioUltra trams and trains are powered by biomethane or green hydrogen-powered engines accompanied by zero emissions lithium-ion battery packs or flywheels, allowing rail-based systems to be used much more widely providing an affordable zero climate change lightweight transport system – eliminating lethal air pollution.

The BioTrams can accommodate up to 210 passengers, 54 seated and 156 standing, travelling at speeds of at least 70km/h (50 mph) between stops. The driveline draws on a double-bogie powertrain allowing for a smoother ride quality for passengers.

The hybrid driveline is powered through two small combustion engine gensets providing power to the lithium-ion battery pack, charged by the engines and through the capture of brake energy recovery requiring no external power from the national grid or overhead wires, a substantial saving as the catenary generally accounts for around 30% of total capital costs. A flywheel option for kinetic energy storage has also been developed for use in the pilot vehicle at Long Marston. This ultra-low emissions design through the biomethane power source provides a wholly circular economy solution.

The use of ultra-lightweight trains / trams in built-up and rural environments would significantly help towards achieving the UK government’s ambition of reaching a net zero emission status. Trains / trams with steel wheels travelling along steel rails require 85% less power than wheels with inflated rubber tyres and deliver greater environmental benefits requiring significantly less energy and emitting minimal airborne particulates. Whilst zero emissions tailpipe emissions have been targeted by the Department for Transport, 84-90% of road-based vehicle emissions are non-exhaust emissions (NEE) (Timmers, R.J.H., Achten P.A.J. 2016), with tyre emissions 1,850 times higher than tailpipe emissions (Emissions Analytics, 2023).

‘The use of ultra-lightweight railcars/trams in built-up and rural environments would significantly help towards achieving the UK government’s ambition of a net zero emission status’

Unique selling points

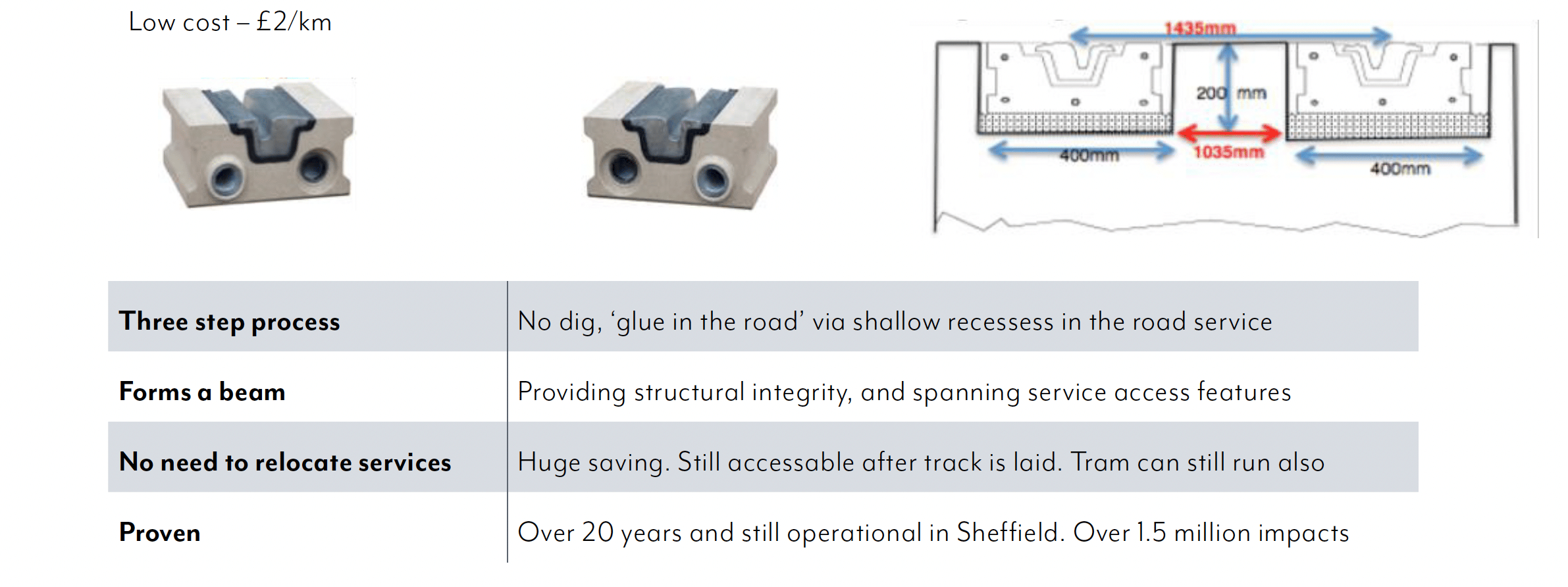

Ultra light rail vehicles have an axle weight of under 5 tonnes. This means a 210-person vehicle weighs close to 20 tonnes (compared to many urban trams weighing over 50 tonnes) resulting in an installed rail cost of £2million per km.

Operating on biomethane or green hydrogen provides greater opportunities for energy security as both fuels are renewable and can be produced in the West Midlands, as well as nationally.

Biomethane as a fuel is completely independent of the electricity grid, which will be under increasing pressure as cars switch to electric propulsion and homes to heat pumps, with many more vehicles, including trains, also looking to increase use of electric power. WMCA (West Midlands Combined Authority) figures estimate that if all cars in the West Midlands were to become electrically powered, three times the electric power would be required to power these vehicles alone.

‘Operating on biomethane or green hydrogen provides greater opportunities for energy security’

As a rule of thumb, 1kg of Biomethane has the same calorific value as 1 litre of diesel, or 0.25kg of hydrogen and is equivalent in output terms to approximately 1 litre of diesel or petrol. At any pressure, the volumetric energy density of methane exceeds that of hydrogen by a factor of 4.7.

With mandatory food collections anticipated from 2025, cities and metropolitan areas have the opportunity to create a circular economy net zero transport solution providing energy security and locally generated renewable fuel provision, which can be supplied to, and used from, the local gas grid. PMOL’s (Pre Metro Operations Ltd) actual experience shows that their entire annual fuel consumption would require merely two days of the biomethane production from the existing Severn Trent Green Power Stourbridge anaerobic digestion facility.

Operating a hybrid drivetrain powered by two very small gensets (0.9 litre, or less than the engine in a family saloon car) and battery pack (or flywheel) provides a 1,000km range and the vehicle does not require any overhead catenary and associated infrastructure or expensive grid connections. Switching to battery power would reduce range to c30km. If a flywheel alone were used, as was the case in our 1998-2000 Bristol tram pilot, range would also be reduced – dependent on external charging either from the grid or a battery pack.

Whilst a battery tram with electrical regeneration might just manage a full day’s work before needing the battery recharged, the energy losses of energy regeneration have a marked effect in an operational regime that requires frequent stop-starts. To be certain that the charge given will last for a day’s work, battery powered trams either require at least double the battery capacity required for running at constant speed, or the means to recharge during the day. This can be done if there are charging points at the termini during the lay-over between services but adds significantly to overall project costs. If instead a larger battery is installed, this will significantly increase the vehicle mass and that in turn will increase both the constant speed running loss and the loss due to the many stops (Huber, M. 2023, The Viability of Battery Trams).

Using flywheel regeneration however, the stop-start losses are only about one third of those from an electrical regeneration system and this enables a significantly smaller capacity battery to be used. Although comparative first costs for the two systems are not easily to hand, over time the cost of operating with flywheel regeneration should be much less, since fewer batteries are required to be replaced less often and the flywheel is unlikely to need replacement at all with the total energy use reduced, because less is wasted.

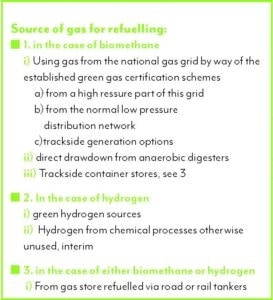

Refuelling equipment is limited to one depot for the entire route. The current service and refuelling schedule envisages trams travelling up to 270 miles in a 17 hour day, and requiring only a ten minute-refuelling stop after three days of operation.

Trackside storage options

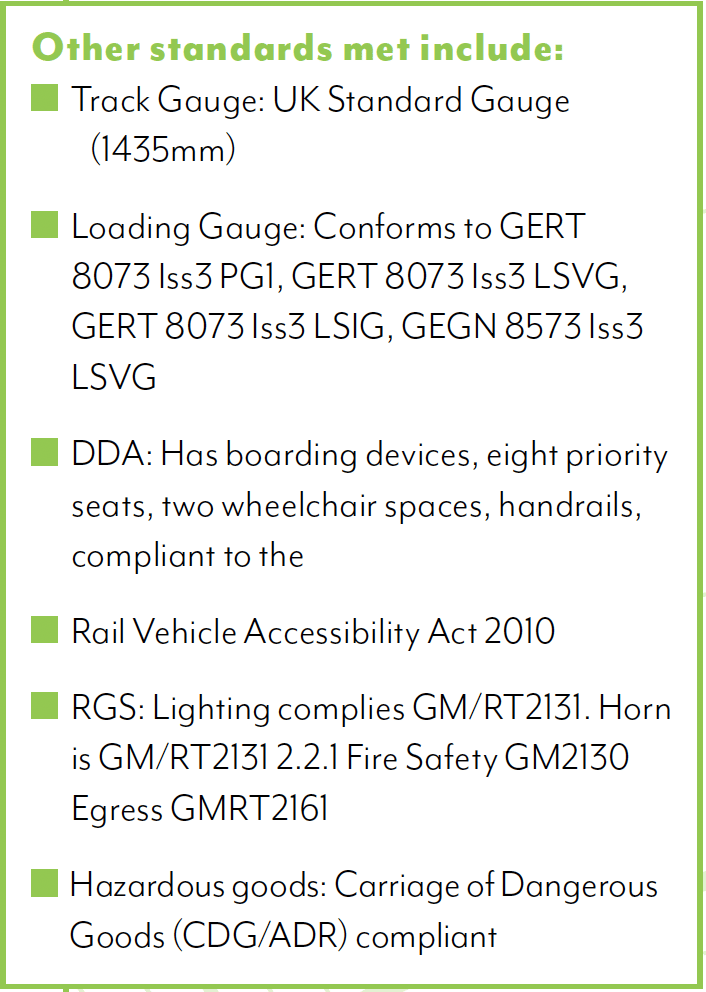

ULRP’s BioUltra is fully compliant, specifically delivering crashworthiness to Category P – III of (GMRT2100) EN15227_ Railroad_crashworthiness_standard, and enabling travel on mixed-use rail lines through enhanced integrity drawing on its spaceframe design.

Innovations machinery integration

Track

Rail track ULRP proposes the use of an innovative but tried and tested low profile track system. This can then be laid quickly, at about 100 metres a week, allowing roads to remain open, with minimal disruption to give smooth, quiet and long life tracks. It can be laid without the need to relocate under street utilities, therefore reducing track cost to less than half that of other track systems that need deep excavations of roads and the relocation of existing underground services.

Other benefits include

- Full traffic compatibility (rail and road vehicles).

- Low pressures into road structure (less than 200 kN/m2).

- Low/No stray currents resistivity more than 1000 Ω /km.

- Less noise and vibration (under 20Hz ~ 30dB, 100Hz ~ 10dBA, track natural frequency ~ 800Hz).

- Transition rail available to existing girder rail profiles.

- Compatible with main line trains, tested to 80 tonne axle load for tunnel enlargement

- Curves down to 12m radius

- Energy efficiency –four times better than rubber tyres, saving scarce renewable energy(note that biomethane exists naturally and does not suffer the 68per cent energy loss in converting renewable energy to hydrogen).

- Vehicle durability - saving embedded energy and materials = cost saving (normal tram durability 30+ years (Blackpool example is 50 - 100+ years) compared to buses 12 years.

- Railtrack compatibility with pedestrian zones (unlike buses) enabling extended zones to eliminate town centre car congestion and reduce pollution

- Popularity of rail vehicles - established record of high modal shift from cars to public transport + increase in adjacent property values

- Low maintenance cost of rails (no rutting of roads which occurs along bus lanes)

Fuel supply

The renewable natural gas, biomethane, is available from common waste products including sewage sludge, food, plant and organic wastes, meat processing waste, poultry and cattle manure. The Anaerobic Digestion and Bioresources Association (ADBA) estimates that over 140mT of organic material is wasted each year in Britain including around 10mT of food waste.

In addition to reducing environmental pollution and greenhouse warming, capturing biomethane and using it as a fuel offers the ultimate economic solution with ultra-low emissions and a wholly local circular environmental operation with security of supply and control of fuel costs. As stated by the International Energy Agency, the United Nations and recently (7th Dec 2022) confirmed by Lord Deben as president of the Climate Change Committee, the use of biomethane as a fuel causes no climate change whatsoever.

Biomethane has been used worldwide to power all forms of transport including over 24 million methane-powered road vehicles. It has been readily adopted by HGVs and buses including in Nottingham, Reading, Peterborough, Bristol, Reading, Darlington, Sunderland, Merseyside, but it has not yet been adopted for rail-based transport in the UK.

‘Biomethane is a significant but underexploited renewable energy resource that is 100 per cent renewable compared to electricity’

97% of the 12million tonnes of animal manure produced annually is unprocessed and the resultant methane emissions are over 80 times more harmful as a greenhouse gas than carbon dioxide. Collecting and processing sewage and manures provides a natural circular economy solution that leads to a net negative carbon emission solution through these significant methane emissions savings.

Biomethane is a significant but underexploited renewable energy resource that is 100% renewable compared to grid electricity which is, at best, today c50% from zero emissions sources.

Great Britain and, in particular, the West Midlands possess leading capacity and corporate expertise. With biomethane production possible from all organic sources, including farmed algae, supply can be greatly increased. Alongside this, innovations from industry are enabling ever greater efficiencies to optimise the range of difficult feedstocks through, for example, micronisation and additives, which can be used to increase biomethane yields from existing and new facilities. In addition, being able to de-water the digestate will reduce storage and transport costs whilst capturing more nitrogen, phosphorus and potassium in the solids.

There are a number of West Midlands’ organisations including Severn Trent, Severn Trent Green Power, Aquabio, Air Liquide, CNG Services, which have significant biogas facilities. For example, it is possible for one significantly food waste-fed biomethane plant requiring 50k tonnes of organic waste to produce 40k-50kMWh a year at a capital cost of around £25 million to install and representing a means for the country to become far more energy resilient.

Comparable fuel costs

- 1m3 of biomethane produces the equivalent of 6.7kWh of energy.

- Biomethane costs only one tenth of the price of hydrogen and is readily available nationwide.

- Biomethane requires only a quarter of the amount of biomethane compared to hydrogen as hydrogen has a much lower density and takes up much more space even when compressed to 700 bar. Operators experimenting with hydrogen as a rail fuel are experiencing challenges achieving sensible range without a separate tender vehicle to store the fuel.

Technology department

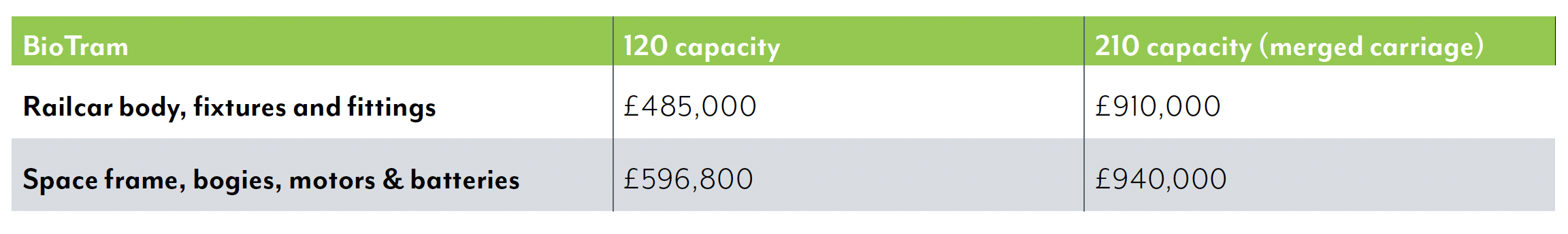

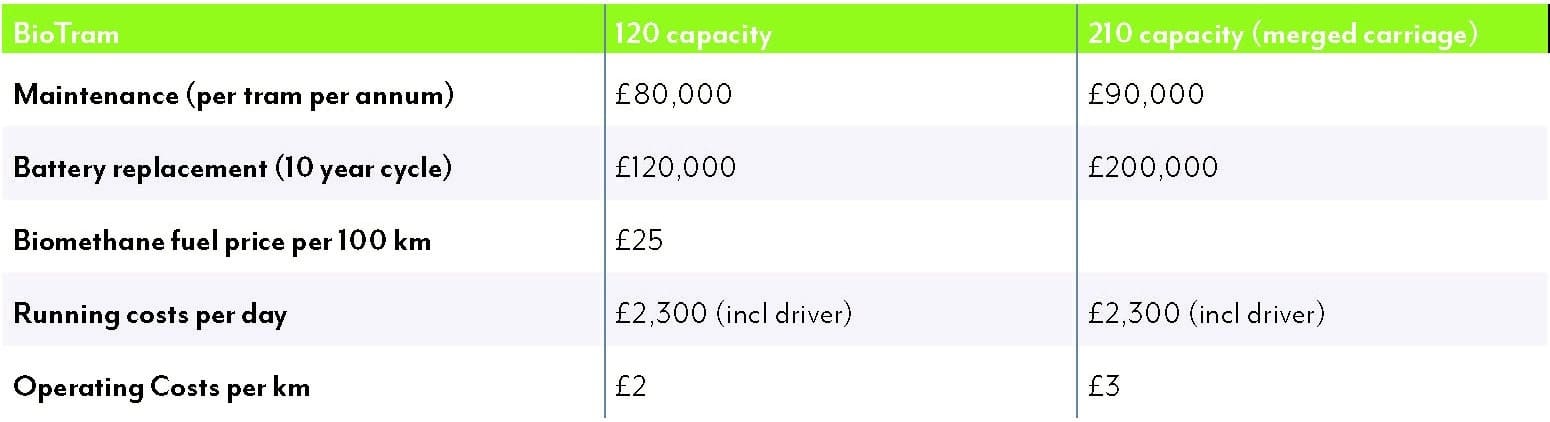

This technology is promoted as an affordable option providing a complete circular systems solution. The first BioTram would be produced at a cost of circa £2million.

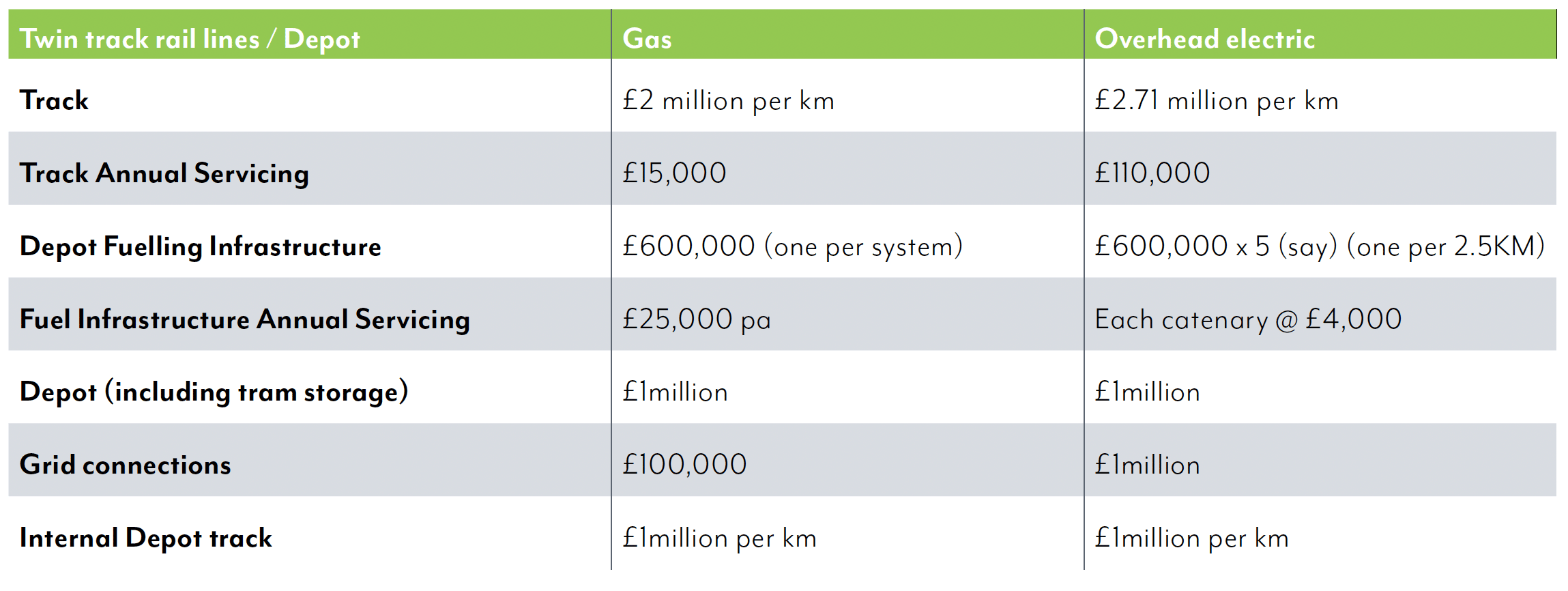

The lightweight track would cost circa £2million per km with no overhead lines required compared with up to £30million per km cost for the electric tramway.

A single refuelling station is required with a £600k capital cost and £20k per annum servicing cost.

Capital expenditure

Ultra Light Rail Partners Ltd creates solutions for rail and on-street lightweight rail, integrating innovators, rail operators, manufacturers, planners and architects. Its goal is to improve the lives of people in urban and semi-rural areas, helping communities, developers and local authorities to solve their future transport needs.

Note: Our best estimates are included here.

Operating expenditure

Installation expenditure comparisons with overhead electric powered trams

Potential Markets

The UK

Until the 1950s the standard urban public transport in UK was provided by trams. Some 20,000 trams operated in 135 UK towns (list available). With the advent of the motor car and the provision of tarmac roads, electric trams with insulated tracks and overhead catenary systems became unnecessarily expensive and diesel buses replaced them. The modern imported electric tram is more like a train. Despite their manifest attractions and advantages these mass transit systems are too expensive to install and operate in any but the larger, richer towns and cities. The rest have no real alternative at present other than buses. BioTrams can resolve this problem, by providing the reliability, consistency, luxury and much appreciated benefits of trams, at a much lower capital and operational cost than a bus. Having no catenary system and no high voltage electric currents the installation and infrastructure cost of the Ultra Light BioTram is easily amortised within the first 12 years of operation, the working lifetime of a bus. Thereafter the system will continue to operate at a fraction of the cost of a bus. BioTrams could very quickly be adopted worldwide with the UK now having the opportunity to lead the market before competition takes over.

EU, US

The UK could pioneer the rapidly growing market for low cost BioTrams in smaller towns before local competition follows.

Africa, Asia, Latin America and Pacific Rim countries

150+ countries have now signed the Global Methane Pledge and are committed to cutting their methane emissions by 30% before 2030. Organic waste is a major source of methane emissions that needs urgently to be processed. The opportunity to use this unrecognised, but potentially valuable resource, to solve the problem of providing urban public transport will open up a massive new international market for the country that pioneers the introduction of BioTrams.

References

Emissions Analytics, (2023), How tyre emissions hide in plain sight, January 17th 2023, accessed 13th February 2023 How tyre emissions hide in plain sight — Emissions Analytics

Timmers, V., Achten P., (2016), Non-exhaust PM emissions from electric vehicles, March 2016, Atmospheric Environment 134, DOI: 10.1016/j.atmosenv.2016.03.017, available from https://www.researchgate.net/publication/297889793_Non-exhaust_PM_emissions_from_electric_vehicles [accessed Jan 17 2023].

ADVERTISE WITH US

450,000+ page views per month

73,000+ newsletter subscribers

Adverts from £1,000 per year

News stories from £100

Rail Business Daily’s market leading news and profile enhancement services enable your business to tell your story to the wider rail community. Engage with thousands of readers via our rail news platforms, including the hugely popular 7am newsletter, rail news website and Rail Director magazine. If you want to do more work in rail, Rail Business Daily is the place to be.

CONTACT US

-

0113 2082620

0113 2082620

-

info@railbusinessdaily.com

info@railbusinessdaily.com

-

15 Mariner Court, Wakefield WF4 3FL

15 Mariner Court, Wakefield WF4 3FL

RailBusinessDaily is an asset owned by the Railway Industry Association, Company no: 10036044. Registered in England and Wales. Copyright RailBusinessDaily 2023. All Rights Reserved.